Actemium’s 21P11 Environment Interface (EI) is the result of years of targeted feedback from our trusted industry partners who require continuous environment monitoring of their production areas to ensure they comply with company and government requirements. FDA 21 CFR Part 11 compliance was a high priority for design team.

Environment Monitoring Solutions

The Environment Interface (EI) key features include:

- Environment monitoring (inputs for new and existing instrumentation)

- Engineered with Audit Trails in mind (parameter logs, personnel entry logs, cleaning logs, maintenance logs, and calibration records)

- Room setpoints automatically changed based on the product being manufactured or activity being performed

- Individual based security access (glove friendly touchscreen and/or RFID)

- Door Access Control

- Wired and wireless communication options to connect to your supervisory system

- Build for a washdown environment

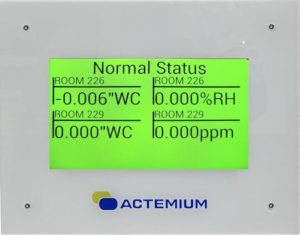

Actemium’s 21P11 possesses the ability to monitor all aspects of a room by integrating with new and/or existing systems and sensors. The Environment Interface (EI) provides point of entry information, local monitoring with warning and critical alarms, room access control features, maintenance, cleaning, and personnel access logbook features. It can operate independently for standalone applications or be connected to an existing or new environment monitoring system with a wider network of devices via Ethernet, Serial, or WiFi communications.

Actemium’s Environment Interface is designed to be part of a facility’s ALCOA+ system when connected with a properly designed Supervisory Control and Data Acquisition system (SCADA). To adhere to regulations and support the quality of production, facilities must be able to quickly and clearly present relevant data. When an EI functions as part of a facility’s larger environment monitoring system, it will assist companies by supporting the creation of audit trails, personnel entry logs, parameter logs, cleaning logs, maintenance logs, and calibration records that will meet compliance requirements. Available in wired (serial and Ethernet) and Wi-Fi communication options, an EI can connect to existing Programmable Logic Controllers (PLCs) or directly to Supervisory Control and Data Acquisition (SCADA) systems.