CHALLENGE:

Sleeman Breweries in Chambly, Quebec needed to improve quality, reduce waste, and boost daily brewing capacity. Their brewhouse relied on manual processes with limited automation, slowing production. With new equipment being added, Sleeman required a modernized control system to automate valves, pumps, and key process inputs across the entire brewhouse.

SOLUTION:

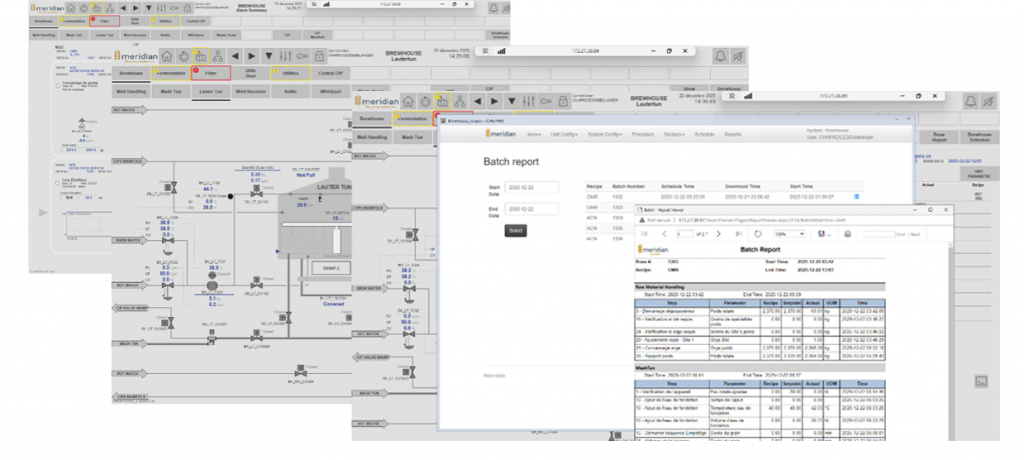

Actemium Toronto redesigned the brewhouse’s electrical and control architecture to deliver a fully automated system. The team upgraded the operation with modern Rockwell automation technology and enhanced control equipment, creating a more streamlined, reliable, and efficient brewing environment. Leveraging PlantPAx, HistorianSE, FactoryTalk SE, and Meridian BrewSoft, Actemium reprogrammed every major stage of the brewhouse—from malt handling through the full CIP process—ensuring seamless, end‑to‑end automation.

The new system delivered an exceptional startup:

- Day 1: 1 brew

- Day 2: 3 brews

- Day 3: 10 brews

RESULT:

With Meridian BrewSoft, operators now have full visibility into real-time process data and can seamlessly manage the complexities of brewing operations. The platform enables brewers to:

- Standardize and automate production workflows

- Access a centralized system for reporting and recipe management

- Quickly respond to process deviations through immediate data access

- Manage the brewhouse from any connected device

- Configure automation sequencing and reporting with reduced complexity

These enhancements significantly reduce operator workload and support consistent, high-quality brewing with minimal room for error.